Grafit Elektroda Puting 3tpi 4tpi Nyambung Pin T3l T4l

Katrangan

Pentil elektroda grafit minangka bagean cilik nanging penting ing proses nggawe baja EAF. Iki minangka komponen sing bentuke silinder sing nyambungake elektroda menyang tungku. Sajrone proses nggawe baja, elektroda diturunake menyang tungku lan diselehake ing kontak karo logam molten. Arus listrik mili liwat elektroda, ngasilake panas, sing nyawiji logam ing tungku. Pentil nduweni peran penting kanggo njaga sambungan listrik sing stabil ing antarane elektroda lan tungku.

Parameter teknis

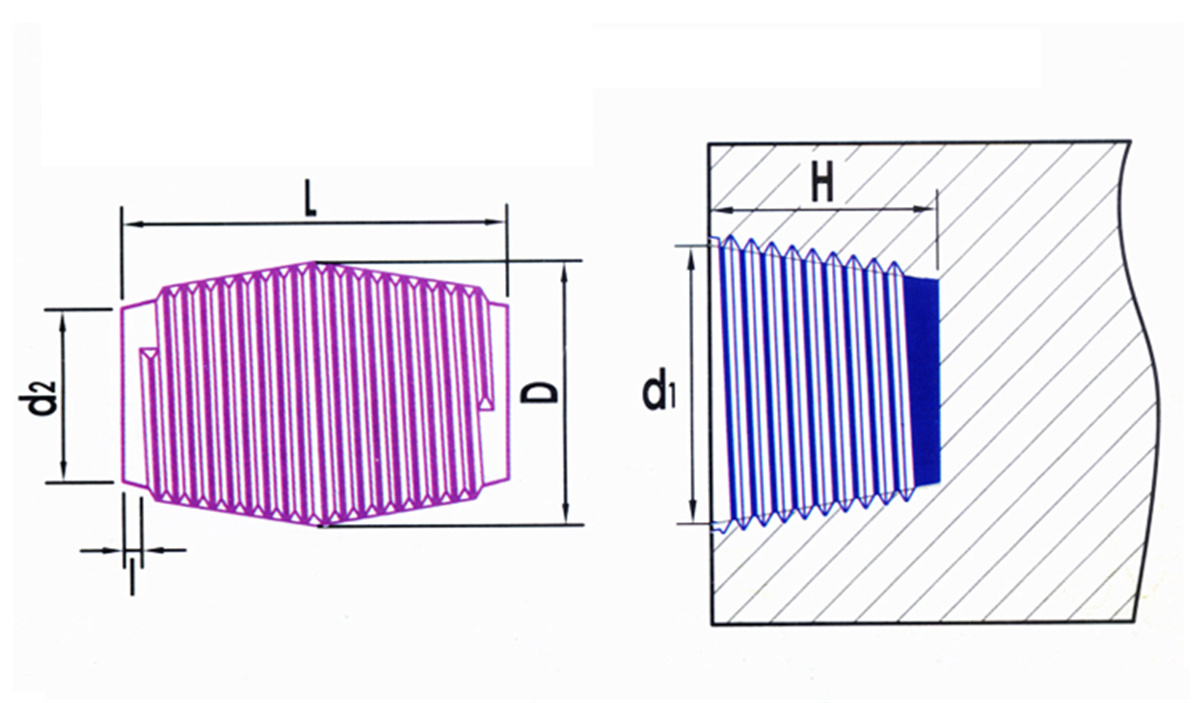

Gufan Carbon Conical Nipple lan Gambar Soket

| Diameter nominal | Kode IEC | Ukuran Puting (mm) | Ukuran Soket (mm) | Pitch | |||||

| mm | inch | D | L | d2 | I | d1 | H | mm | |

| Toleransi (-0.5~0) | Toleransi (-1~0) | Toleransi (-5~0) | Toleransi (0~0.5) | Toleransi (0~7) | |||||

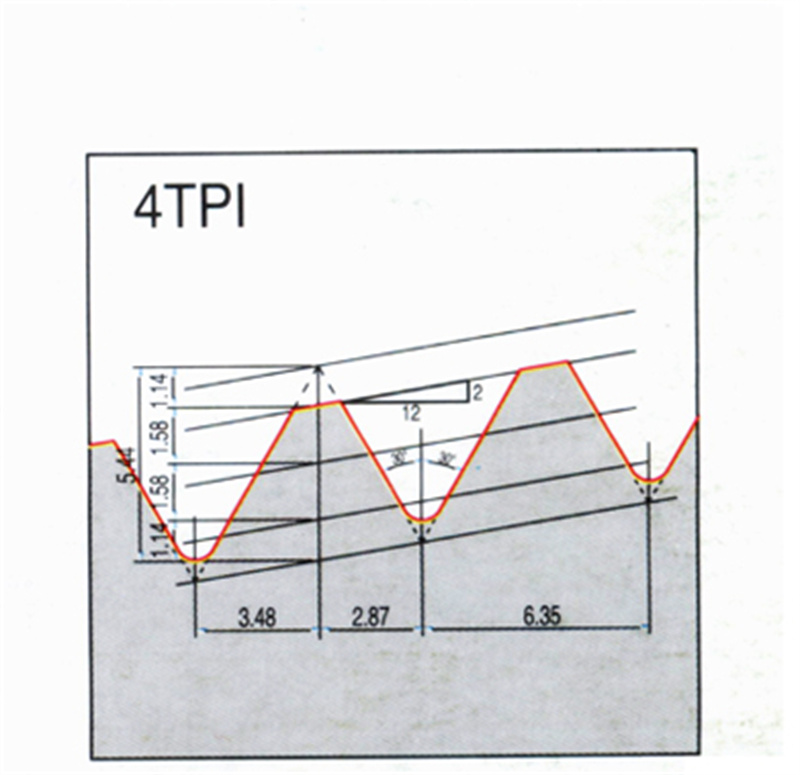

| 200 | 8 | 122T4N | 122.24 | 177.80 | 80.00 | <7 | 115.92 | 94.90 | 6.35 |

| 250 | 10 | 152T4N | 152.40 | 190.50 | 108.00 | 146.08 | 101.30 | ||

| 300 | 12 | 177T4N | 177.80 | 215.90 | 129.20 | 171.48 | 114.00 | ||

| 350 | 14 | 203T4N | 203.20 | 254.00 | 148.20 | 196.88 | 133.00 | ||

| 400 | 16 | 222T4N | 222.25 | 304.80 | 158.80 | 215.93 | 158.40 | ||

| 400 | 16 | 222T4L | 222.25 | 355.60 | 150.00 | 215.93 | 183.80 | ||

| 450 | 18 | 241T4N | 241.30 | 304.80 | 177.90 | 234.98 | 158.40 | ||

| 450 | 18 | 241T4L | 241.30 | 355.60 | 169.42 | 234.98 | 183.80 | ||

| 500 | 20 | 269T4N | 269.88 | 355.60 | 198.00 | 263.56 | 183.80 | ||

| 500 | 20 | 269T4L | 269.88 | 457.20 | 181.08 | 263.56 | 234.60 | ||

| 550 | 22 | 298T4N | 298.45 | 355.60 | 226.58 | 292.13 | 183.80 | ||

| 550 | 22 | 298T4L | 298.45 | 457.20 | 209.65 | 292.13 | 234.60 | ||

| 600 | 24 | 317T4N | 317.50 | 355.60 | 245.63 | 311.18 | 183.80 | ||

| 600 | 24 | 317T4L | 317.50 | 457.20 | 228.70 | 311.18 | 234.60 | ||

| 650 | 26 | 355T4N | 355.60 | 457.20 | 266.79 | 349.28 | 234.60 | ||

| 650 | 26 | 355T4L | 355.60 | 558.80 | 249.66 | 349.28 | 285.40 | ||

| 700 | 28 | 374T4N | 374.65 | 457.20 | 285.84 | 368.33 | 234.60 | ||

| 700 | 28 | 374T4L | 374.65 | 558.80 | 268.91 | 368.33 | 285.40 | ||

| Diameter nominal | Kode IEC | Ukuran Puting (mm) | Ukuran Soket (mm) | Pitch | |||||

| mm | inch | D | L | d2 | I | d1 | H | mm | |

| Toleransi (-0.5~0) | Toleransi (-1~0) | Toleransi (-5~0) | Toleransi (0~0.5) | Toleransi (0~7) | |||||

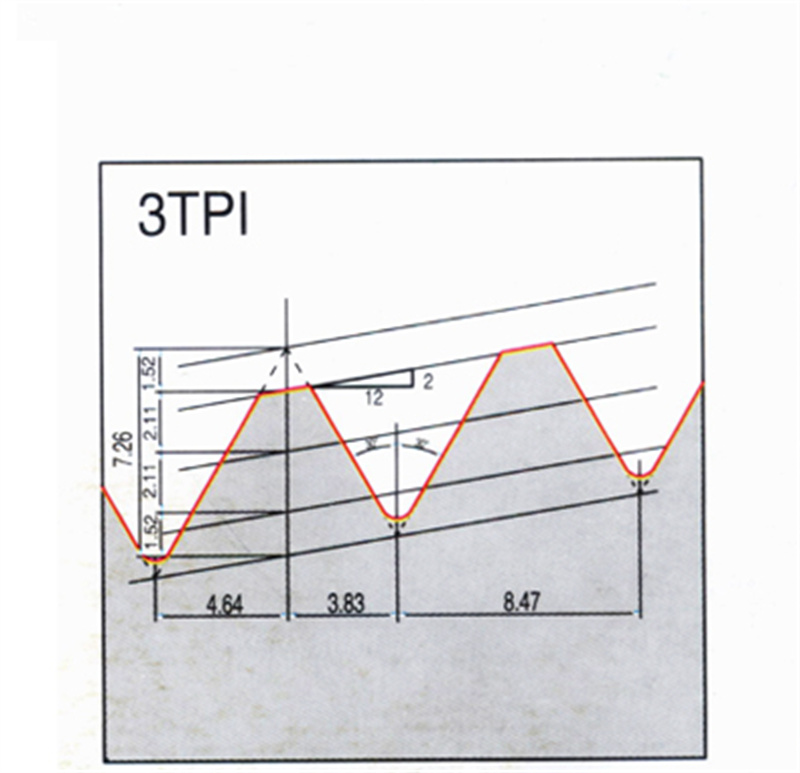

| 250 | 10 | 155T3N | 155.57 | 220.00 | 103.80 | <7 | 147.14 | 116.00 | 8.47 |

| 300 | 12 | 177T3N | 177.16 | 270.90 | 116.90 | 168.73 | 141.50 | ||

| 350 | 14 | 215T3N | 215.90 | 304.80 | 150.00 | 207.47 | 158.40 | ||

| 400 | 16 | 241T3N | 241.30 | 338.70 | 169.80 | 232.87 | 175.30 | ||

| 450 | 18 | 273T3N | 273.05 | 355.60 | 198.70 | 264.62 | 183.80 | ||

| 500 | 20 | 298T3N | 298.45 | 372.60 | 221.30 | 290.02 | 192.20 | ||

| 550 | 22 | 298T3N | 298.45 | 372.60 | 221.30 | 290.02 | 192.20 | ||

| Elektroda | Bobot standar saka puting susu | ||||||||

| Ukuran Elektroda Nominal | 3TPI | 4TPI | |||||||

| Diameter × Dawane | T3N | T3L | T4N | T4L | |||||

| inch | mm | lbs | kg | lbs | kg | lbs | kg | lbs | kg |

| 14 × 72 | 350 × 1800 | 32 | 14.5 | - | - | 24.3 | 11 | - | - |

| 16 × 72 | 400 × 1800 | 45.2 | 20.5 | 46.3 | 21 | 35.3 | 16 | 39.7 | 18 |

| 16 × 96 | 400 × 2400 | 45.2 | 20.5 | 46.3 | 21 | 35.3 | 16 | 39.7 | 18 |

| 18 × 72 | 450 × 1800 | 62.8 | 28.5 | 75 | 34 | 41.9 | 19 | 48.5 | 22 |

| 18 × 96 | 450 × 2400 | 62.8 | 28.5 | 75 | 34 | 41.9 | 19 | 48.5 | 22 |

| 20 × 72 | 500 × 1800 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 84 | 500 × 2100 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 96 | 500 × 2400 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 110 | 500 × 2700 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 22 × 84 | 550 × 2100 | - | - | - | - | 73.4 | 33.3 | 94.8 | 43 |

| 22 × 96 | 550 × 2400 | - | - | - | - | 73.4 | 33.3 | 94.8 | 43 |

| 24 × 84 | 600 × 2100 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| 24 × 96 | 600 × 2400 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| 24 × 110 | 600 × 2700 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| Diameter elektroda | inch | 8 | 9 | 10 | 12 | 14 |

| mm | 200 | 225 | 250 | 300 | 350 | |

| Easing Momen | N·m | 200–260 | 300–340 | 400–450 | 550–650 | 800–950 |

| Diameter elektroda | inch | 16 | 18 | 20 | 22 | 24 |

| mm | 400 | 450 | 500 | 550 | 600 | |

| Easing Momen | N·m | 900–1100 | 1100–1400 | 1500–2000 | 1900–2500 | 2400–3000 |

Instruksi Instalasi

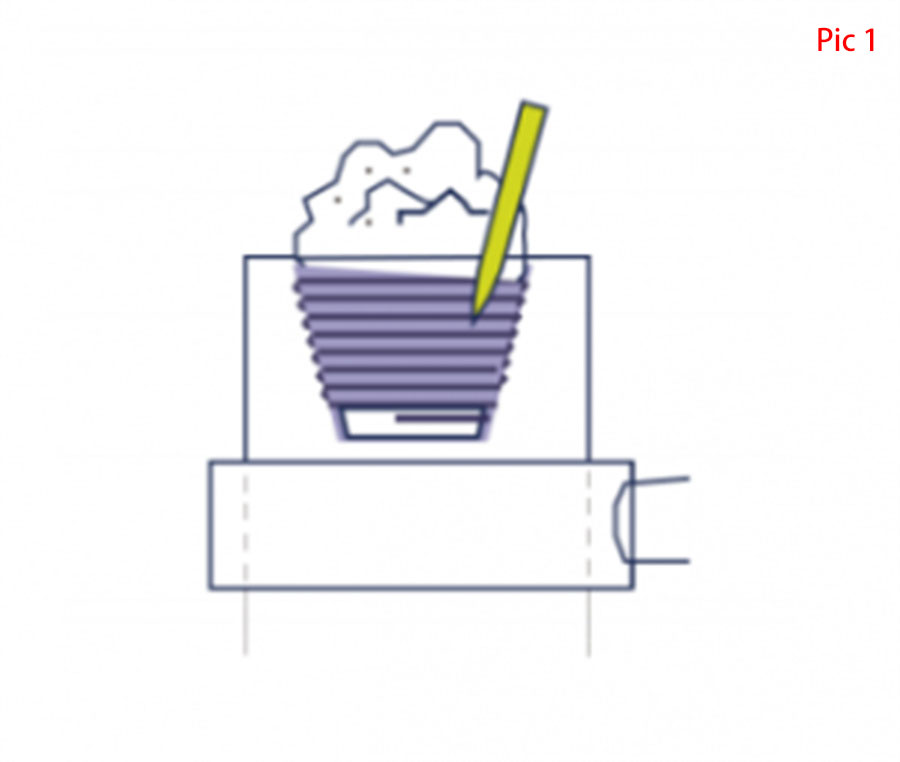

- Sadurunge masang pentil elektroda grafit, resik bledug lan rereget ing lumahing lan soket elektroda lan pentil karo udara teken; (ndeleng pic1)

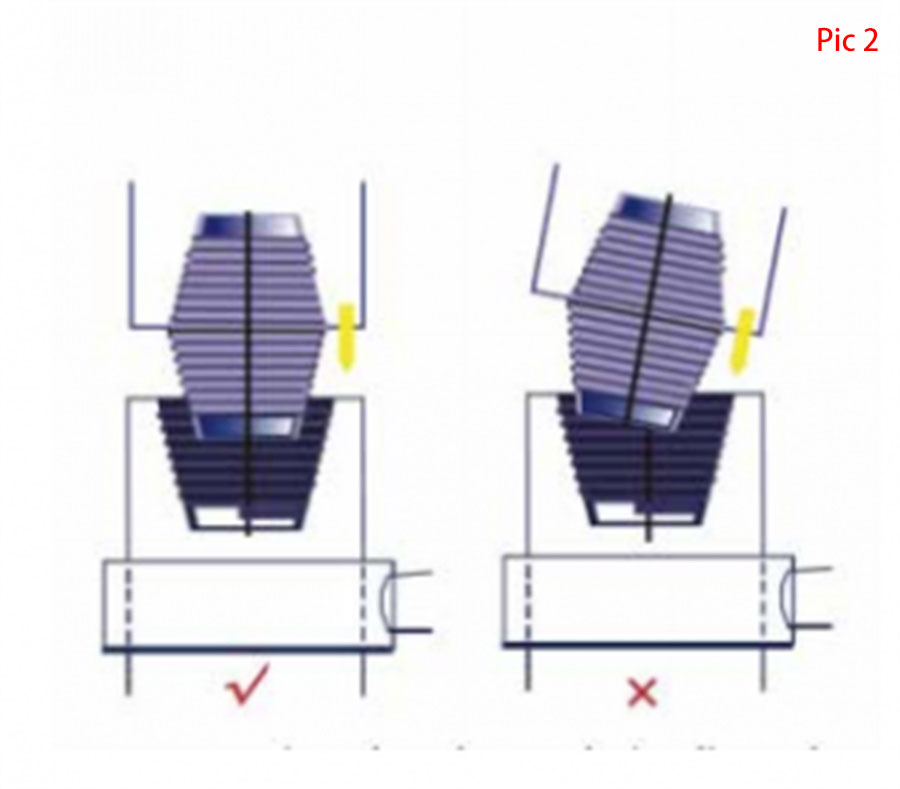

- Ing baris tengah grafit elektroda pentil kudu katahan konsisten sak rong bêsik grafit elektroda gabungan bebarengan; (ndeleng pic2)

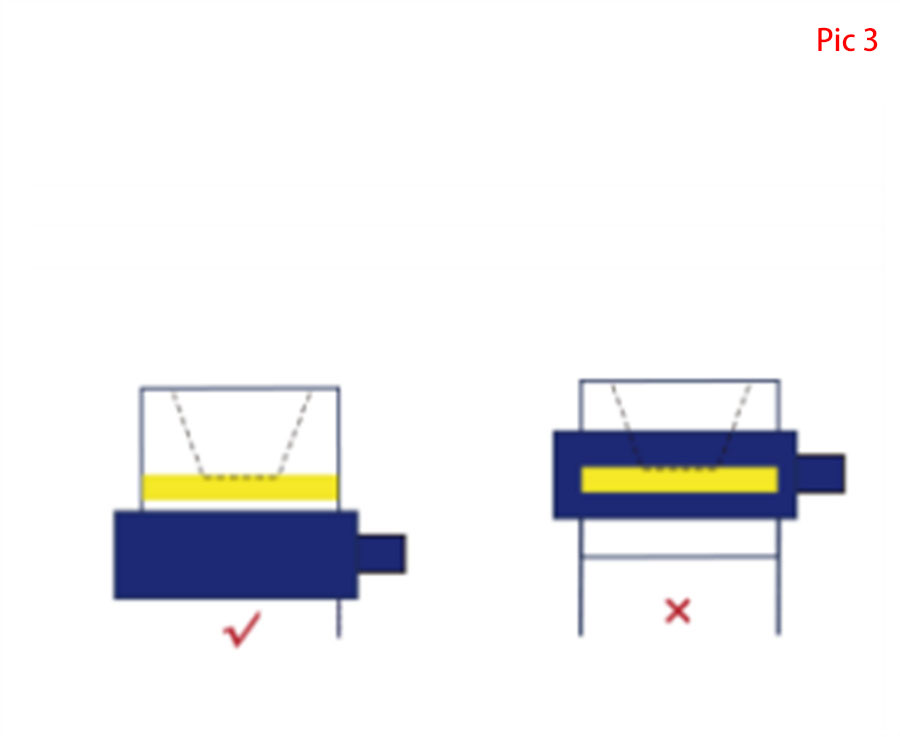

- Clamper elektroda kudu ditahan ing posisi sing tepat: ing njaba garis safety saka ujung sing luwih dhuwur; (ndeleng pic3)

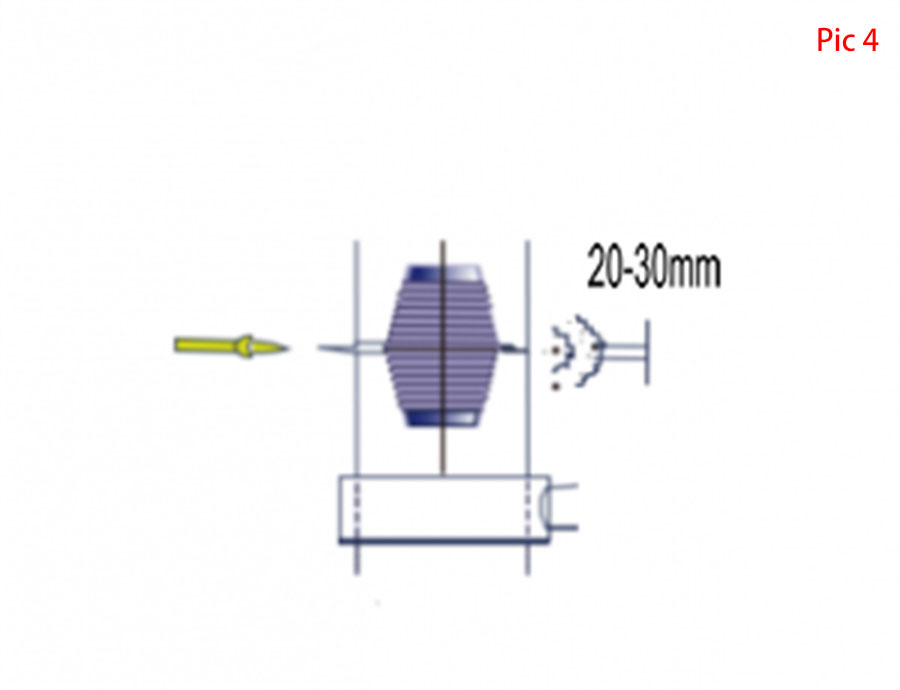

- Sadurunge ngencengi pentil, priksa manawa permukaan pentil resik tanpa bledug utawa reged. (ndeleng gambar 4)

Pentil elektroda grafit minangka komponen kritis ing proses nggawe baja EAF. Kualitas kasebut langsung mengaruhi efisiensi lan linuwih proses kasebut. Nggunakake puting berkualitas tinggi penting kanggo nyegah kacilakan elektroda lan mesthekake proses nggawe baja sing lancar lan produktif.Miturut data industri, luwih saka 80% kacilakan elektroda disebabake dening puting rusak lan tripping longgar. Kanggo milih puting susu sing tepat, faktor ing ngisor iki kudu dianggep.

- Konduktivitas termal

- Resistivitas listrik

- Kapadhetan

- Kekuwatan mekanik

Nalika milih pentil elektroda grafit, penting kanggo nimbang kualitas, ukuran, lan wujude, lan kompatibilitas karo spesifikasi elektroda lan tungku. Kanthi milih puting sing tepat, produsen bisa nambah kualitas baja lan nyuda biaya sing ana gandhengane karo downtime lan produktivitas sing kurang.

Kalebu konduktivitas termal, resistivitas listrik, Kapadhetan, lan kekuatan mekanik.